Roll Mining Mill Efficiency Calculation

.jpg)

Optimization of working parameters of highpressure roller mill

2024年11月15日 In order to improve the crushing efficiency of highpressure roller mill and reduce energy consumption, the optimal parameter combination of highpressure roller mill is 2022年1月30日 The Morrell method for predicting the specific energy consumption of conventional crushing, High Pressure Grinding Rolls (HPGRs), and tumbling mill equipment is well known and widely applied in(PDF) TheMorrellMethodtoDeterminethe 2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parametersAnalysis and Optimization of Grinding 2020年10月20日 The method for determining the optimal productivity, as well as the technical and economic indicators of modern continuous thinsheet cold rolling mills, was presented Productivity Optimization of Cold Rolling Mills

IMPROVEMENT OF OPERATIONAL EFFICIENCY OF COLD

2019年10月3日 Roll consumption at the 4stand mill was 30% higher compared to the 5stand cold rolling mill All of that required a comprehensive analysis of the process parameters and 2021年3月19日 In this paper we have derived suitable rolling force formula and setting value for bending force for obtaining good strip shape Equal load of rolling power and good shape as A Calculation Procedure and Optimization for Pass 2024年5月24日 The low efficiency of tumbling mills is documented in literature with Wills (2016) referencing sources which estimate values between 1% and 26% (1), and Bouchard et al Vertical Roller Mills used for the comminution of mineral 2017年9月13日 In grinding, operating Efficiency compares the operating work index of a comminution machine to the Bond work index from bench scale crushing and grindability tests How to Calculate Grinding Mill Operating Efficiency

.jpg)

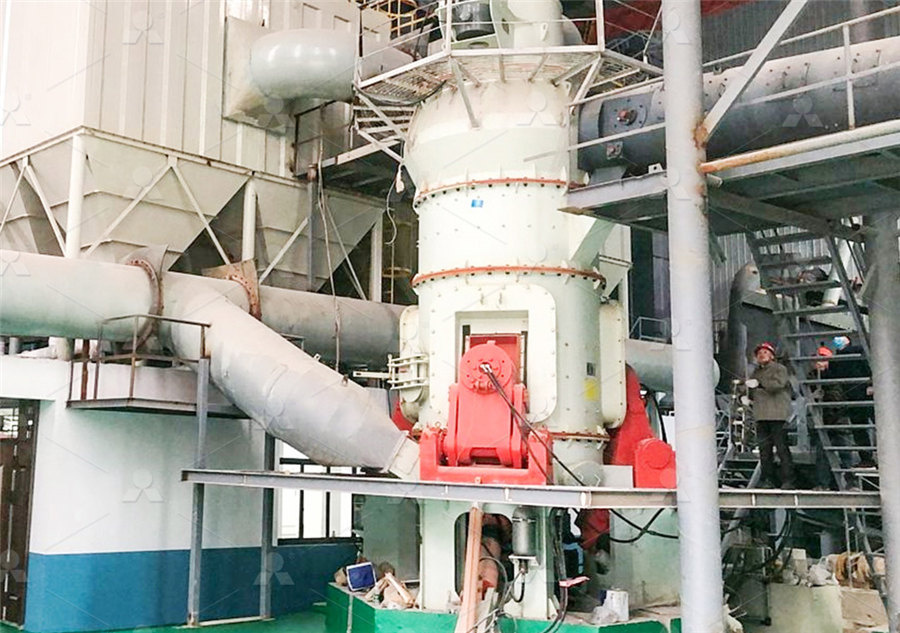

Rethinking Grinding Efficiency in Ball Mills CEEC (Coalition

2024年9月27日 The Coalition for Energy Efficient Comminution (CEEC) has been established and is supported by a broad range of mining sector companies keen to accelerate awareness, 2009年5月1日 High Pressure Grinding Rolls (HPGR) circuits have the potential to reduce the Mining Industry’s CO2 emissions by up to 345 megatonnes/year, or 435% when compared to the established Autogenous Predicting the overall specific energy 2024年10月15日 Our team of experts will help global customers develop a reliable, energysaving and highefficiency vertical roller mill grinding solution by taking advantage of our Vertical Roller Mills Cement 2022年3月30日 Comminution is a major contributor to the Mining Industry’s carbon footprint As most of the world’s leading mining companies have formally committed themselves to having Helping to reduce mining industry carbon emissions: A step

A rapid calculation method for predicting roll deformation of

A rapid calculation method for predicting roll deformation of sixhigh rolling mill Li Xie 1Anrui He 1Chao Liu 1 1 National Engineering Research Center for Advanced Rolling Technology, 2015年10月14日 Calculate a Classifier and Screen’s Efficiency Classifier and screen performance formula : Classification efficiency is generally defined as the weight ratio of Calculate a Classifier and Screen's Efficiency 911Metallurgist2016年2月1日 A case study was undertaken at a gold mine in the Free State on the influence of the fragment size distribution on 'free gold', the effect of ore loss and dilution on the mill efficiency, and time Monitoring ore loss and dilution for mineto 2015年10月15日 The effect of mill speed on energy input was studied in a mill of 03m diameter and 025m long with 40% charge filling The total charge weight was 54 kg The variation in Mill Critical Speed Calculation 911Metallurgist

.jpg)

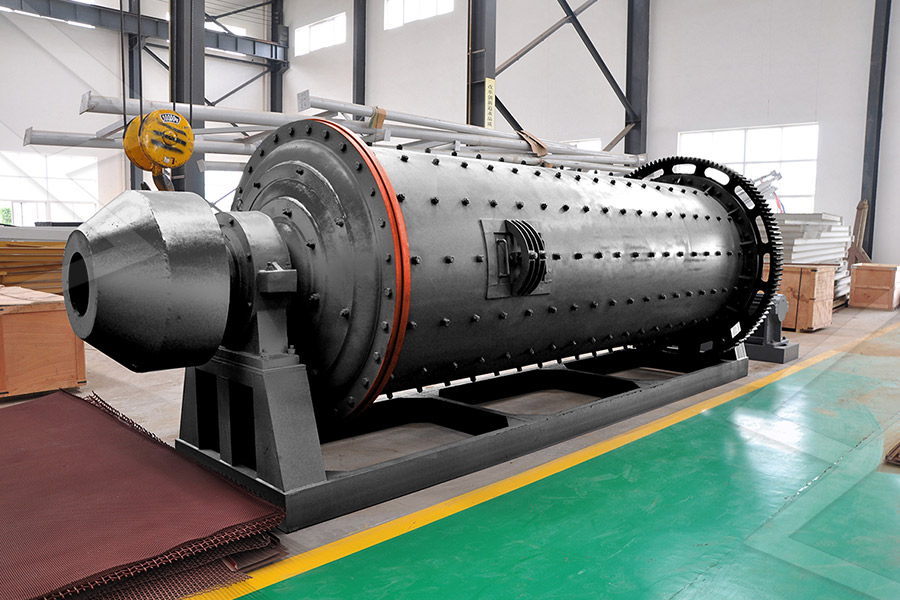

Factors Affecting Ball Mill Grinding Efficiency

2017年10月26日 a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this 2013年7月15日 The ball mill in closed circuit with hydrocyclones is an industry standard, and well known methodologies exist for equipment sizing, selection and designEnergy Efficient Ball Mill Circuit – 2015年2月25日 The document discusses the history and evolution of coal crushers It begins with an overview of the importance of crushing coal and the early developments Crushing of coal and calculation of 2024年3月1日 2 Design Analysis and Calculations 21 Roll Crusher Geometry It is necessary to estimate the maximum size of the mineral particles that can be fed into the machine for a Design, Fabrication and Testing of a Double Roll Crusher

.jpg)

Circulating Load Calculation Formula

2015年2月21日 For example your ball mill is in closed circuit with a set of cyclones The grinding mill receives crushed ore feed The pulp densities around your cyclone are sampled and known over an 8hour shift, allowing to 2022年3月15日 The communition process represents approximately half the energy consumption of a mine site (CEEC, 2013) Improving process control reduces variability and Unifying highpressure grinding rolls models ScienceDirect2013年4月1日 The role of classification in milling appears to have been neglected in the current efforts to reduce the energy consumption of grinding Two past approaches, experimental and Closed circuit ball mill – Basics revisited ScienceDirectdetailed calculation of capacity and roll crusher – Gold Ore Crusher Crushing Plant Design and Layout Considerations Mine haultruck capacity is an important factor at primary crusher calculation of crushing roll capacity – Grinding Mill China

.jpg)

(PDF) TheMorrellMethodtoDeterminethe

2022年1月30日 The Morrell method for predicting the specific energy consumption of conventional crushing, High Pressure Grinding Rolls (HPGRs), and tumbling mill equipment is well known and widely applied in 2018年1月1日 The tradeoff capacity maximization vs operational efficiency is highlighted and it is shown that capacity optimization might hide operational inefficiency © 2017 The Authors Thermal properties of oxide scale on surface of work roll in 2013年9月1日 The calculation of force for a roll system has significant effects on cold rolled thin strip gauge adjustment of a 20high Sendzimir mill According to the rolling parameters and Calculation and Analysis of Force in Roll System of 20High Sendzimir Mill2016年6月1日 Historically there has been three basic ways of grinding ore, hammer mills, rolls, or wet tumbling mills Hammer mills and rolls are not used that often and then usually only for Rod Mills: Efficient Grinding Solutions

.jpg)

Rethinking Grinding Efficiency in Ball Mills CEEC (Coalition

2024年9月27日 The Coalition for Energy Efficient Comminution (CEEC) has been established and is supported by a broad range of mining sector companies keen to accelerate awareness, 2009年5月1日 High Pressure Grinding Rolls (HPGR) circuits have the potential to reduce the Mining Industry’s CO2 emissions by up to 345 megatonnes/year, or 435% when compared to the established Autogenous Predicting the overall specific energy 2024年10月15日 Our team of experts will help global customers develop a reliable, energysaving and highefficiency vertical roller mill grinding solution by taking advantage of our Vertical Roller Mills Cement 2022年3月30日 Comminution is a major contributor to the Mining Industry’s carbon footprint As most of the world’s leading mining companies have formally committed themselves to having Helping to reduce mining industry carbon emissions: A step

.jpg)

A rapid calculation method for predicting roll deformation of

A rapid calculation method for predicting roll deformation of sixhigh rolling mill Li Xie 1Anrui He 1Chao Liu 1 1 National Engineering Research Center for Advanced Rolling Technology, 2015年10月14日 Calculate a Classifier and Screen’s Efficiency Classifier and screen performance formula : Classification efficiency is generally defined as the weight ratio of Calculate a Classifier and Screen's Efficiency 911Metallurgist2016年2月1日 A case study was undertaken at a gold mine in the Free State on the influence of the fragment size distribution on 'free gold', the effect of ore loss and dilution on the mill efficiency, and time Monitoring ore loss and dilution for mineto 2015年10月15日 The effect of mill speed on energy input was studied in a mill of 03m diameter and 025m long with 40% charge filling The total charge weight was 54 kg The variation in Mill Critical Speed Calculation 911Metallurgist

.jpg)

Factors Affecting Ball Mill Grinding Efficiency

2017年10月26日 a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this 2013年7月15日 The ball mill in closed circuit with hydrocyclones is an industry standard, and well known methodologies exist for equipment sizing, selection and designEnergy Efficient Ball Mill Circuit –